Mechanical engineering department have good & knowledgeable facilities and technical staff that have ability to share good knowledge to students about mechanical engineering ,having very good infrastructure and labs which occupied with good practical models and machineries which is very helpful for students to understand the practical application of engineering .

Shri Ram Institute of Technology offers bachelor of technology in Mechanical Engineering. We had a team of highly qualified, experienced, matured and dedicated faculty members who are committed to carve a name in the top echelons of the academic & professional world.

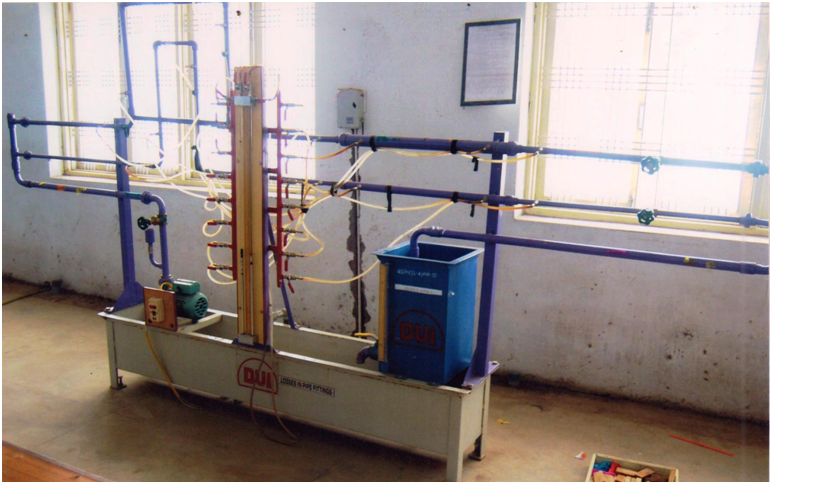

The Department has laboratory and workshop facilities with state-of-the-art equipment to carry out research in all areas related to Mechanical Engineering.

Our objective is not to merely produce professionals capable to serve their own needs but Endeavor to serve the society with great concern for human values.

I wish success to all students in your endeavour to join us on the journey of quality education & to have a great learning experience with my excellent, loving & caring team.

Dr Vivek Nema

(Head of Department)

Mechanical Engineering

VISION

To acquire academic excellence in mechanical engineering education and research, keeping dynamic equilibrium with its professional, social, ethical and economic environment in global perspective.

MISSION

M1 Prepare distinctive quality students in mechanical engineering who are able to apply the acquired knowledge successfully with engineering professional ethics and disseminating its research findings to serve society.

M2 To convert students into mechanical professionals and entrepreneurs by communicating creativity and moral values.

M3 To encourage students to learn about emerging technologies in order to continue higher education and lifelong learning.

Program Outcome

- Engineering Knowledge : Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem Analysis: Identify, formulate, review research literature, and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

PROGRAM EDUCATIONAL OBJECTIVES

PEO1

To be able to apply the acquired technical knowledge to engineering problems professionally and ethically using modern tools and methods.

PEO2

To be able to communicate effectively while working in a team with multi disciplinary approach to investigate and analyze engineering problems and design and develop solution for the same.

PEO3

To develop lifelong ability to relate engineering issues to broader social and ecological context.

Program Specific Outcomes

PSO1

A Mechanical engineering graduate should be able to do analysis, design, development, implementation or oversight of more advanced mechanical system or processes.

PSO2

A Mechanical engineering graduate should be prepared to work professionally, individually or in group in mechanical systems areas while taking course in each area.

PSO3

A Mechanical engineering graduate should have knowledge impact of engineering technology, solution in societal and global context.

FLUID MACHANICH LAB APPARATUS

HYDRAULIC RAM APPARATUS

CAPLAN TURBIME

PELTON TURBINE

FRANCIS TURBINE

FORCED VORTEX FLOW

IMPACT OF JET ON VANES APPARATUS

BERNOULLI’S APPARATU

RECIPROCATING PUMP

LOSS IN PIPE FITTING APPARATUS

NOTCH TANK APPARATUS

VENTURI METER AND ORIFICE METER APPARATUS

PITOT TUBE APPARATUS

CENTRIFUGAL PUMP APPARATUS

REYNOLD APPARATUS

PIPE FRICTION APPARATUS

ORIFICE MOUTHPIECE TANK APPARATUS

RAC LAB

ICE PALNT TRAINER

REFRIGERATION AND AIRCONDITIONING EXPERIMENTATION BENCH

GENERAL CYCLE REFRIGERATION TRAINER

AIR AND WATER HEAT PUMP TRAINER

HEAT AND MASS TRANSFER LAB APPARATUS

a) THERMAL CONDUCTIVITY OF METAL ROD APPARATUS

b) THERMAL CONDUCTIVITY OF LIQUID APPARATUS

c) DROP AND FILM CONDENSATION APPARATUS

a) HEAT TRANSFER IN NATURAL CONVECTION APPARATUS

b) STEFAN VOLTZMAN APPARATUS

a) THERMAL CONDUCTIVITY OF INSULATING POWDER APPARATUS

b) THERMAL CONDUCTIVITY OF SOLID (GAURDED HOT PLATE) APPARATUS

c) HEAT TRANSFER THROUGH COMPOSITE WALL APPARATUS

PARALLEL FLOW AND COUNTER FLOW HEAT EXCHANGER

a) HEAT TRANSFER IN PIN -FIN APPARATUS

b) EMMISIVITY MEASURMENT APPARATUS

a) HEAT TRANSFER THROUGH LAGGED PIPE APPARATUS

b) HEAT TRANSFER IN FORCED CONVECTION APPARATUS

SHELL AND TUBE HEAT EXCHANGER

IC ENGINE LAB APPARATUS

FOUR STROKE FOUR CYLINDER PETROL ENGINE

FOUR STROKE SINGLE CYLINDER DIESEL ENGINE

TWO STROKE SINGLE CYLINDER PETROL ENGINE

ROTARY COMPRESSOR

TWO STAGE RECIPROCATING AIR COMPRESSOR TEST RING

Development activities

- Product Development

| Developed E-vehicles, Energy saving stove | 2021-2022 |

| Online Presentation due to Covid -19 | 2020-2021 |

| Developed Pedal Pump , Corn Sheller | 2019-2020 |

Instructional materials

- Question Banks comprising of indicative set of questions are given to students in all theory courses as mandatory practice

- Lab Manual of lab courses

- Instructional material in theory courses

Working models/charts/monograms etc.

Several working models and charts for performing experiments are being displayed in the department and laboratories as shown above.

Research laboratories

- Instrumentation Laboratory

- Material Testing (UTM) Machine

- CNC Laboratory

- Computer-Aided Design Laboratory

- Automobile Workshop

- Mechanical Workshop

- Plastic Moulding Machine

- Multimedia Laboratory

- Computer with i3 Processor 4 GB ram and 500 GB Storage